Array

Array

Industrial cutting laser

Development of an on-line monitoring system for a high power industrial cutting laser

Our client asked:

TRUMPF provides manufacturing solutions in the fields of machine

tools, laser technology, electronics and Industry 4.0. It was looking

for an on-line monitoring system for a high power (10kW) industrial

cutting laser.

The project story:

The challenge that was presented to us was that the lasers need

regular trimming in order to maintain their cutting efficiency, but any

sensor placed in the beam is instantly destroyed.

By monitoring the temperature on the rear of a silicon mirror, we

could infer the optical beam profile of the laser.

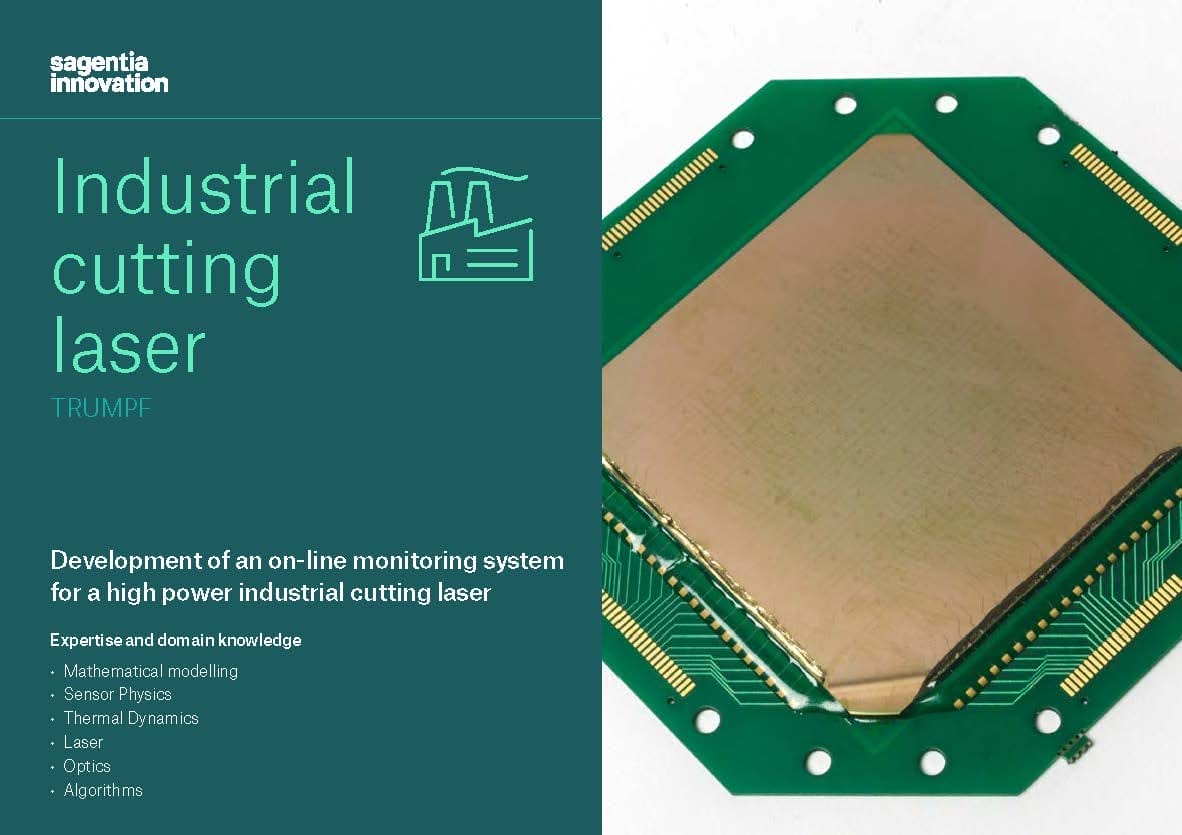

We created a sensor array as an array of diodes that could be

integrated into the fabric of the silicon mirror using standard

lithographic techniques.

Algorithms converted the temperature array data into an accurate

representation of the laser beam’s optical profile.

Utilising a 2500 pixel MEMS optical beam sensor array, allowed rapid

set-up and continuous monitoring of the laser beam’s profile in order

to ensure consistent operation of that laser.

Results: deliverables and outcomes

TRMPF still uses this system to continually monitor and auto-trim

their cutting lasers.

Our markets

Our consultants, scientists and engineers redefine what’s possible and help R&D groups across the medical, industrial, consumer and food and beverage sectors achieve commercial return from their opportunities.

Our projects

We have completed over 10,000 projects for start-ups and global market leaders alike, from understanding the market & technology landscape through to developing and delivering complex products.