CCUS – insights, opportunities, and technical challenges

by Jocelino Rodrigues, PhD – Principal Analyst; Carlo Bardoli – Senior Consultant, and Michele Turitto PhD – Managing Partner (Industrial, Chemicals, & Energy)

Carbon capture, utilisation, and storage (CCUS) can play a significant part in reducing emissions whilst ensuring continued operational stability across several industries, particularly in hard-to-abate industries such as chemicals, steel, and cement, which account for almost 20% of global CO2 emissions1. So what’s on the agenda in CCUS?

Commitment to ambitious climate targets aligned with the Paris Agreement has led to the introduction of new drivers – such as emissions trading systems (ETS) – combined with incentives – such as innovation funds, carbon levies, and tax credits – from national governments and supranational unions to sustain CCUS uptake.

This favourable regulatory regime is expected to reverse a historic trend that has seen a limited level of deployment for CCUS projects. As such, it has drawn interest from organisations across the entire value chain, including CO2 emitters, energy companies, technology companies, storage site operators, and financial institutions. These organisations are interested in understanding the answers to the challenges that persist about the commercial sustainability, scalability, and long-term technical viability of CCUS. In this blog, we provide an overview of such challenges and the role that technologies can have in addressing them.

CCUS implementation insights

CCUS deployment has historically been limited, though it is projected to grow in the near future. As of mid-2023, the IEA reports 40 commercial CCUS projects in operation across industrial processes, fuel transformation, and power generation2.

Retrofitting CCUS into existing facilities is noteworthy for legacy emissions reduction, making an immediate impact. Retrofitting into older infrastructure can, however, be challenging due to constraints from plant design and equipment. Successful cases, like SaskPower’s Boundary Dam project in Canada and the Petra Nova project in the USA, showcased the ability to retrofit a coal-fired power plant with post-combustion capture6. Strong government incentives played pivotal roles in the FID of these projects. Petra Nova was shut down in 2020 due to sinking oil prices caused by the COVID-19 pandemic7 – however, earlier this year, it was announced that it would return to service owing to increased credits for CO2 sold for utilisation and increased price of petroleum8. Petra Nova illustrates the volatile nature of CCUS scalability, specifically highlighting project sensitivity to market and regulatory changes. In the UK, the Longannet and Hunterston projects had a similar fate due to challenges associated with high costs, financial uncertainty, commercial viability, and changing market dynamics9,10. In contrast, Norway boasts two enduring success stories with the Sleipner and Snøhvit projects11.

Lessons learned from unsuccessful projects are driving improvements and supporting the maturing of technologies and processes. Governments and industries are actively addressing barriers to enhance viability. This optimism is illustrated by the 2023 UK budget, which included a £20 billion investment for developing CCUS12. The UK Department for Energy Security and Net Zero recently announced the Net Zero Teesside Power (NZT Power) project as one of the first CCUS clusters in the UK – and its construction is already under way13.

At aggregate level, as of March 2023, operational CCUS projects were capturing 46 Mt of CO2 per year, with an additional capacity of 21 Mt per year under construction, expected to be completed by 2030. In addition to this, there are plans to drastically increase the capture capacity by a further 254 Mt per year by 2030. Meeting this ambitious goal will depend on successfully addressing existing technical challenges in the field14.

Technical challenges span the entire CCUS value chain

CAPTURE

In the CO2 capture space, amine-based chemical absorption is the most mature solution, having been used for decades to remove CO2 from natural gas. Despite this, significant system-level innovation opportunities exist:

- System configurations for new applications (i.e., pre-treatment of incoming gas stream and absorber design)

- Optimising energy usage and temperature requirements

- Solvent performance upon exposure of different contaminants

- Application of existing technologies at different scales

- Reducing solvent losses

- Addressing solvent toxicity

- Improvement of performance in presence of oxygen

- Modularisation of plant for cost reduction through quicker build times and delivery on demand.

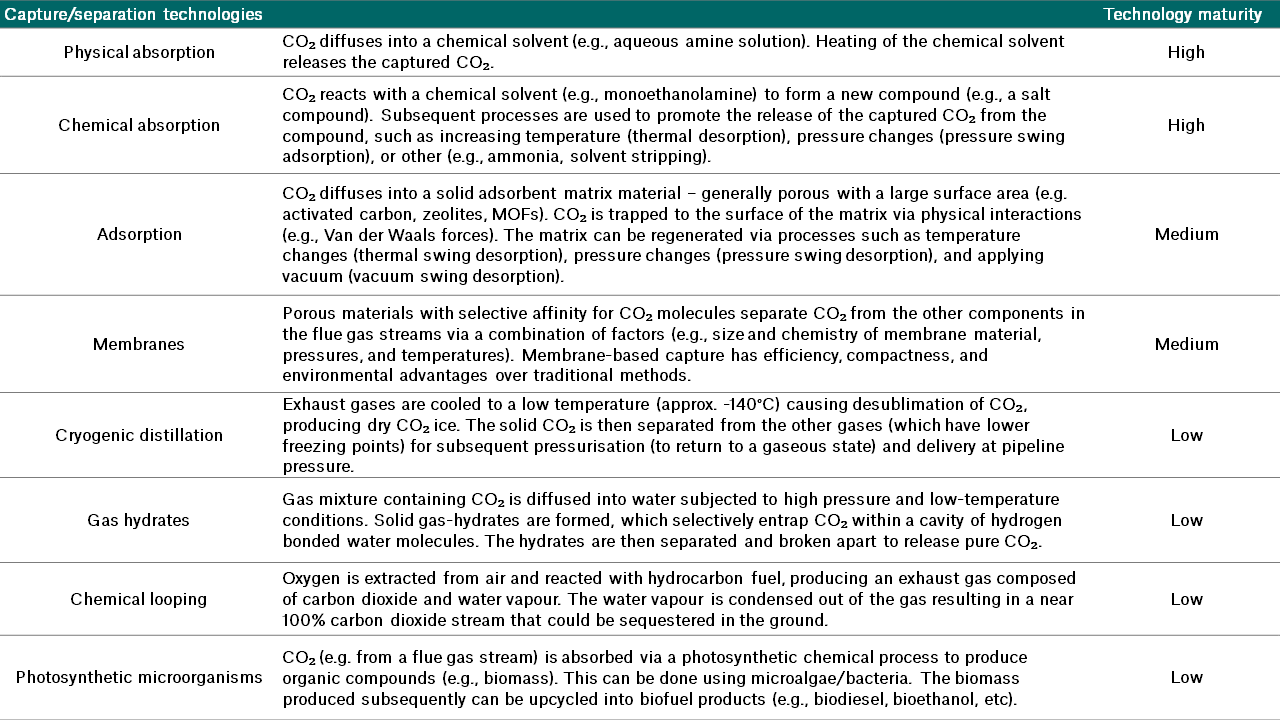

Further opportunities to achieve improved efficiencies also exist for post-combustion capture and separation methods – these are captured below.

CO2 capture is only part of the equation as other impurities need to be carefully handled. For example, nitrogen and oxygen can decrease the critical temperature, resulting in overpressure during injection.

On the injection front, the main challenges are associated with the handling of fluid at low temperatures (can be as low as -80C) due to Joule Thompson effect. The equipment (typically transferred from the oil & gas market) may not be tested for such low temperatures. Well integrity needs to be carefully managed in these conditions, particularly because of the effects of carbon mineralisation on cement.

STORAGE

Storage is another critical step before and after injection. In fact, extended characterisation analysis is required to identify suitable sites (e.g. presence of top seal, fault density, thickness, extension, number of wells drilled, pressure and temperature). In cases in which depleted reservoirs are used for CO2 storage, some of the former O&G-producing wells need to be plugged and abandoned, which calls for solutions of suitable plugging materials. In some regions, such as Southeast Asia, saline aquifers are also being evaluated as potential storage sites. Long-term storage performance is also critical and demands suitable monitoring approaches addressing different aims; these include, but are not limited to, plume imaging, top seal integrity, migration in the overburden, seismicity and atmospheric detection.

UTILISATION

To date, the most common capture CO2 utilisation route has been in oil and gas for enhanced oil recovery. With an increasingly widespread drive to fulfil Environmental, Social, & Governance (ESG) pledges and comply with regulations, companies from a larger variety of sectors – such as food and beverage, chemical, and industrial – are assessing paths for effective CO2 capture and/or upcycling. The challenge is linked to determining the paths that optimise for effectiveness, sustainability, and value-add. Utilisation options generally fall under two categories:

- Direct CO2 use – e.g. in agriculture, industrial processes, heat transfer in power systems

- Converted CO2 use – e.g. in chemical processes, building materials or fuel production

Examples of applications that, under certain conditions, are proven to be commercially viable include15:

- Building materials – CO2 is used to produce aggregates or in curing wet concrete mix

- Urea – CO2 is used to produce urea via the Haber-Bosch process

- Polymers – CO2 is used to produce polymers such as polycarbonates.

CCUS as a key enabler in a pragmatic route to energy transition

Whilst CCUS may be seen by its detractors as a means to maintain a fossil fuel-centred energy system, it is an important element in ensuring a smoother and more pragmatically achievable energy transition.

From our experience with clients across the CCUS value chain, those who are looking with interest at the potential impact that CCUS can have on emissions reduction need to consider the following key questions:

- What are the opportunities associated with CO2 utilisation that best fit my requirements, ESG pledges, and regulatory drivers?

- What is the landscape for innovative solutions across CO2 separation, injection, and storage?

- As a technology provider, how could the development of my CCUS solution be accelerated? Or how can its performance be enhanced?

- What could be a suitable model to make CCUS commercially viable? And how would this model be impacted by existing and emerging regulations?

- Which companies could be attractive technical or commercial partners?

If these questions resonate with you, do reach out to us. We will be delighted to discuss ways in which we can assist in addressing the challenges associated with CCUS projects and enable the unlocking of their full potential value.

Click here and contact Sagentia Innovation today.

References

- Achieveing Net Zero Heavy Industry Sectors in G7 Members, IEA, 2022 [https://www.iea.org/reports/achieving-net-zero-heavy-industry-sectors-in-g7-membershttps://iea.blob.core.windows.net/assets/c4d96342-f626-4aea-8dac-df1d1e567135/AchievingNetZeroHeavyIndustrySectorsinG7Members.pdf]

- Energy System: Carbon Capture, Utilisation and Storage, IEA, 2023 [https://www.iea.org/energy-system/carbon-capture-utilisation-and-storage]

- CCS Retrofit – Analysis of the Globally Installed Coal-Fired Power Plant Fleet, IEA, 2012 [https://www.iea.org/reports/ccs-retrofit]

- Pan, Ming, et al. "Application of optimal design methodologies in retrofitting natural gas combined cycle power plants with CO2 capture." Applied energy 161 (2016): 695-706.

- Retrofitting CO2 Capture To Existing Power Plants, IEA, 2011 [https://ieaghg.org/publications/technical-reports/reports-list/9-technical-reports/1029-2011-02-retrofitting-co2-capture-to-existing-power-plants]

- Mantripragada, Hari C., Haibo Zhai, and Edward S. Rubin. "Boundary Dam or Petra Nova–Which is a better model for CCS energy supply?." International Journal of Greenhouse Gas Control 82 (2019): 59-68.

- Restart delayed at Texas coal unit linked to Petra Nova CCS project, Reuters [2 Aug 2023] [https://www.reuters.com/business/energy/restart-delayed-texas-coal-unit-linked-petra-nova-ccs-project-2023-08-01/]

- The World's Largest Carbon Capture Plant Gets a Second Chance in Texas, Bloomberg [8 Feb 2023] [https://www.bloomberg.com/news/articles/2023-02-08/the-world-s-largest-carbon-capture-plant-gets-a-second-chance-in-texas?leadSource=uverify%20wall]

- Longannet Fact Sheet: Carbon Dioxide Capture and Storage Project, MIT [https://sequestration.mit.edu/tools/projects/longannet.html#:~:text=The%20UK%20government%20announced%20%22a,government%27s%20competition%20for%20CCS%20funding]

- Hunterston power station plans withdrawn by Ayrshire Power, BBC [26 June 2012] [https://www.bbc.co.uk/news/uk-scotland-scotland-business-18602532]

- The carbon capture crux: Lessons learned, IEEFA [1 Sept 2022] [https://ieefa.org/resources/carbon-capture-crux-lessons-learned]

- Support for households and energy security at the heart of Budget, Department for Energy Security and Net Zero, Great British Nuclear, and The Rt Hon Grant Shapps MP [16 Mar 2023] [https://www.gov.uk/government/news/support-for-households-and-energy-security-at-the-heart-of-budget]

- Net Zero Teesside: Work starts on low-carbon natural gas power station, BBC [27 Sep 2023] [https://www.bbc.co.uk/news/uk-england-tees-66939966]

- CCUS Projects Explorer – A worldwide database of CCUS projects, IEA [https://www.iea.org/data-and-statistics/data-tools/ccus-projects-explorer]

- Hepburn, Cameron, et al. "The technological and economic prospects for CO2 utilization and removal." Nature 575.7781 (2019): 87-97.